The 5 Best Rugged Tablets for Manufacturing in 2026

Introduction to Rugged Tablets in Manufacturing

Why Manufacturing Needs Rugged Mobility

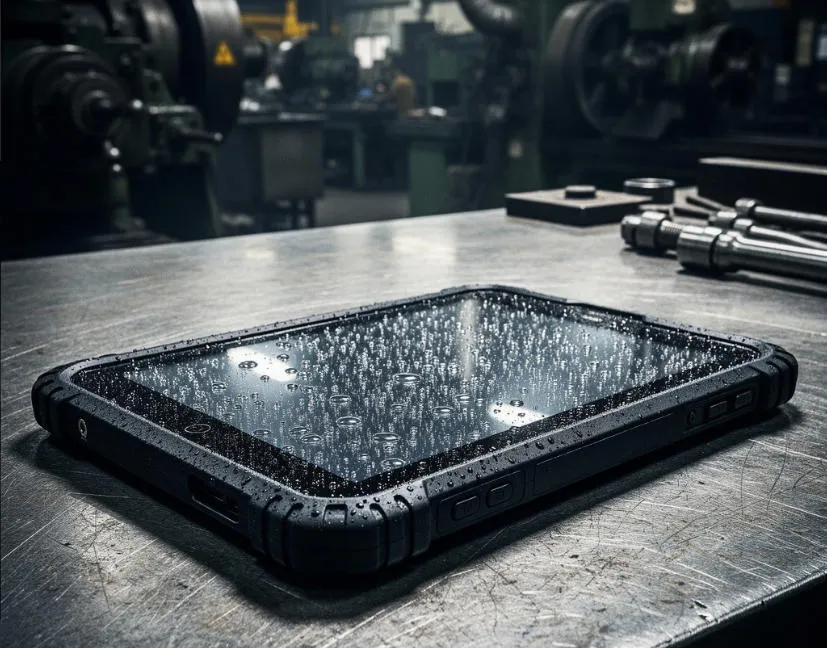

Manufacturing floors aren’t exactly friendly places for consumer electronics. Dust floats through the air, machines vibrate constantly, temperatures shift, and accidental drops happen daily. That’s why rugged tablets have become essential tools in modern factories.

Think of rugged tablets as the industrial equivalent of a steel-toe boot — built not just to function, but to survive.

Workers today rely on mobile devices to monitor production lines, scan inventory, manage maintenance schedules, and access ERP systems in real time. Without durable hardware, digital transformation simply stalls.

The Rise of Industrial Digital Transformation

Industry 4.0 has pushed manufacturers toward connected operations. Sensors, automation systems, and cloud dashboards all generate valuable data — but that data is only useful if workers can access it on the factory floor.

Rugged tablets bridge the gap between machines and people.

What Makes a Tablet “Rugged”?

Durability Standards (MIL-STD-810H and IP Ratings)

A rugged tablet is designed to withstand harsh environments. Most manufacturing-grade devices meet MIL-STD-810H testing standards and offer IP65 or higher protection against dust and water.

This means they can survive:

- Drops from shoulder height

- Heavy vibration from machinery

- Dust-filled environments

- Occasional water exposure

Industrial Connectivity and Performance

Manufacturing tablets must connect reliably to Wi-Fi networks, industrial systems, and sometimes private LTE or 5G infrastructure. Stable connectivity ensures real-time production monitoring without interruptions.

Battery Life and Hot-Swap Capability

Battery Life and Hot-Swap Capability

Factories often operate 24/7. Rugged tablets with hot-swappable batteries allow workers to replace batteries without shutting down the device — eliminating workflow interruptions.

Key Features Manufacturing Teams Should Look For

Sunlight-Readable Displays

Not all manufacturing happens indoors. Logistics yards, loading docks, and open facilities require displays visible in bright light.

Glove and Wet-Touch Operation

Workers wearing protective gloves still need to interact with touchscreens. Rugged tablets support glove-mode and rain-mode input.

Mounting and Vehicle Integration

Forklifts, inspection carts, and industrial vehicles often require mounted tablets for navigation and data entry.

Barcode and RFID Integration

Integrated scanners improve inventory tracking speed and accuracy.

The 5 Best Rugged Tablets for Manufacturing in 2026

Panasonic Toughbook A3

The Toughbook A3 remains one of the most trusted Android rugged tablets in industrial environments. Its modular expansion ports, long battery life, and proven durability make it ideal for production monitoring.

Manufacturers appreciate its reliability and stable performance across long shifts.

Getac ZX10

The Getac ZX10 balances portability and power. Its lightweight design makes it perfect for supervisors moving between production zones while still offering industrial durability.

It’s especially useful for inspection workflows and mobile reporting.

Winmate M101 Series

The Winmate M101 series is widely used in manufacturing automation environments. With multiple I/O ports and optional barcode scanning modules, it integrates easily with factory systems.

Its large display helps operators visualize dashboards clearly.

Samsung Galaxy Tab Active5 Pro

Samsung’s rugged tablet lineup continues to expand into industrial applications. The Tab Active5 Pro combines consumer-level usability with enterprise durability.

For factories already using Android enterprise tools, this device fits seamlessly.

Waysion Industrial Rugged Tablet

Waysion’s WT10RX industrial rugged tablets are designed specifically for vehicle-mounted and factory applications. These devices often include customizable modules, strong vibration resistance, and industrial mounting support.

They’re particularly useful in logistics-heavy manufacturing environments.

Comparing Rugged Tablets for Industrial Use

Performance vs Durability

Some rugged tablets prioritize computing performance, while others focus on extreme durability. Manufacturing companies should balance both based on their workflow needs.

A quality inspection team might prioritize camera and processing power, while forklift operators need vibration resistance.

Cost vs Long-Term Value

Rugged tablets may cost more upfront, but they typically last far longer than consumer devices. Over time, the total cost of ownership is significantly lower.

It’s like buying industrial machinery — reliability saves money.

Real Manufacturing Use Cases

Assembly Line Monitoring

Operators can track production metrics directly from the line.

Warehouse Inventory Control

Barcode scanning tablets eliminate manual counting errors.

Predictive Maintenance

Maintenance teams can access equipment diagnostics instantly.

Quality Inspection Workflows

Inspectors can document issues with photos, checklists, and reports in real time.

Benefits of Rugged Tablets in Smart Manufacturing

Increased Productivity

Workers spend less time returning to control rooms to access information.

Reduced Downtime

Durable devices prevent workflow interruptions caused by hardware failure.

Improved Data Accuracy

Digital forms reduce manual entry mistakes.

How to Choose the Right Rugged Tablet

Assessing Your Factory Environment

Start by evaluating temperature ranges, dust levels, vibration exposure, and mobility requirements.

Software Compatibility Considerations

Ensure the tablet supports your MES, ERP, or warehouse management system.

Planning for Scalability

Choose hardware platforms that can be deployed across multiple facilities.

Future Trends in Industrial Rugged Tablets

AI-Enabled Manufacturing Devices

AI-powered inspection and analytics tools are increasingly being integrated into rugged tablets.

Edge Computing Integration

Edge processing reduces latency and enables faster decision-making on the factory floor.

Conclusion

Rugged tablets have become essential tools in modern manufacturing environments. As factories become smarter and more connected, workers need reliable mobile devices that can survive industrial conditions while delivering real-time data access.

The best rugged tablets for manufacturing in 2026 combine durability, connectivity, performance, and flexibility. Whether used for inspection, inventory control, predictive maintenance, or production monitoring, these devices help manufacturers operate more efficiently and safely.

Choosing the right rugged tablet isn’t just about hardware — it’s about enabling your workforce to work smarter every day.

FAQs

1. Why do manufacturers need rugged tablets instead of consumer tablets?

Consumer tablets are not designed for dust, vibration, or temperature extremes commonly found in manufacturing environments.

2. What operating system is best for manufacturing tablets?

Both Android and Windows rugged tablets are widely used depending on software requirements.

3. How long do rugged tablets typically last?

Most industrial rugged tablets last 5–7 years with proper maintenance.

4. Can rugged tablets integrate with manufacturing software systems?

Yes, they commonly integrate with MES, ERP, and warehouse management systems.

5. Are rugged tablets suitable for forklift mounting?

Yes, many rugged tablets are specifically designed for vehicle-mounted applications.

Latest Content

- Why System Integrators Still Choose Proven Hardware Partners in 2026

- What is a Mobile Data Terminal (MDT)? Ultimate Guide for 2026

- How Rugged Tablets Maximize Field Efficiency

- Mining Operations Redefined: Durable Rugged Tablets for Harsh Environments & Safety

- Mobile Data Terminal: The Ultimate Comprehensive Guide (Updated 2026)