A Technical Look at How Q777 & V7S Enable Connected Operations Across Fleets, Transit, and Warehousing

In modern mobility systems, rugged edge hardware is no longer optional — it is the foundation that allows operators and integrators to connect sensors, vehicles, applications, and cloud platforms into a unified system.This edition takes a deeper technical dive into how WAYSION’s Q777 and V7S rugged in-vehicle tablets are deployed in real fleet, transit, and warehouse environments to enable reliable communication, system integration, and operational continuity.

1. Fleet Management: Real-Time Visibility & Telematics Integration with Q777

Fleet operators today manage increasing operational complexity:

- vehicles operating across vast geographies

- mixed OEM platforms with different protocols

- demand for real-time location & sensor data

- strict requirements for uptime and safety

The Q777 functions as a ruggedized in-vehicle data concentrator — bridging telematics sensors, dispatch platforms, and cloud systems.

Why Integrators Deploy Q777 in Fleet Projects

Multi-GNSS Precision Tracking GPS + GLONASS + Beidou ensures positioning in tunnels, dense cities, mountains, and cross-border routes.

AHD Video Input for Operational Safety One-channel AHD allows for:

- blind-spot cameras

- driver monitoring

- reverse-assist

- incident recording

This reduces infrastructure requirements and simplifies system architecture.

Flexible Interface Capabilities

- RS232/RS485 for telematics accessories

- External CAN adaptor support for vehicle diagnostics

- USB for data logging or peripheral sensors

Built for Harsh, Continuous Use Wide-temperature endurance, vibration resistance, and 24/7 operation make it ideal for long-haul trucks, municipal fleets, oil & energy transport, and emergency vehicles.

Outcome: A single rugged MDT that provides navigation, data collection, tracking, and driver communication — without the failure rates of consumer tablets.

2. Public Transportation: V7S for Driver Terminals, Dispatch, and Passenger Systems

Public transportation vehicles operate under extremely dynamic conditions — heavy sunlight, vibration, frequent stops, and constant data communication.

Why Bus Integrators Prefer V7S

Sunlight-Readable 7” Display + Integrated Sunvisor Ensures clear visibility during:

- east/west routes

- high-reflection environments

- outdoor bus stations

- night-to-day transition shifts

The anti-glare and high-brightness characteristic improves driver reaction time and reduces operation errors.

Robust Connectivity for Transit Systems With 4G LTE + Dual-band Wi-Fi, V7S maintains stable links to:

- AVL/dispatch platforms

- e-ticketing/fare systems

- scheduling & route management

- passenger counting systems

- driver communication consoles

Industrial Interfaces for System Expansion RS232/RS485 allow bus integrators to connect:

- fare boxes

- door control signals

- LED route boards

- environmental sensors

- RFID systems

High Reliability for All-Day Routes Transit requires predictable uptime. The V7S is tested for continuous multi-shift operation, thermal stability, and long-term reliability under driver-interface workloads.

Outcome: A stable driver terminal that supports safety, scheduling, communication, and passenger information — all from one rugged device.

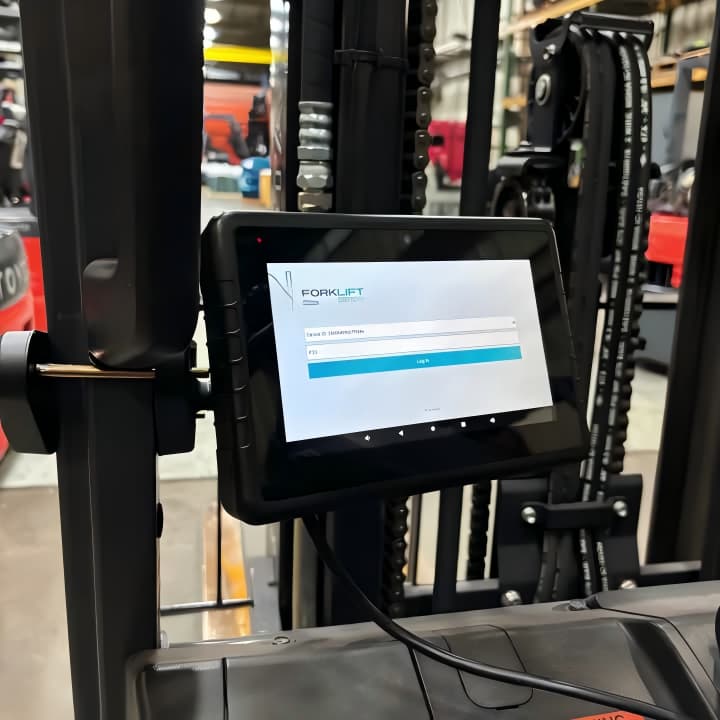

3. Warehouse & Forklift Operations: V7S as the Connected Work Terminal

Warehouse operations depend on real-time data flow across people, equipment, and WMS systems.

Forklifts, especially, operate under:

• strong vibration

dust & temperature variations

• constant movement

• tight aisles & high-traffic zones

How V7S Supports Forklift and Warehouse Digitalization

Reliable Connectivity Inside Large Warehouses Stable Wi-Fi roaming and 4G LTE fallback ensures:

- WMS task assignments

- real-time scanning

- forklift location tracking

- load verification

- job completion sync

This prevents the connectivity dropouts typical of consumer tablets.

Optimized for Heavy Industrial Use Vibration-resistant mounting + wide temperature range = stable forklift terminal for:

- picking

- pallet movement

- dock loading

- long-shift operations

Rugged Build With Minimal Maintenance Needs The V7S reduces failure rates caused by:

- accidental impacts

- cable movement

- battery drift

- overheating

Simple Integration with WMS & MCS Supports browser-based apps, native Android apps, and API-driven software — enabling easy deployment across warehouse platforms.

Outcome: A forklift terminal that remains connected, readable, and responsive in every corner of the warehouse.

Why Integrators and Operators Choose WAYSION

WAYSION rugged tablets deliver consistent performance across fleet, transit, and warehouse environments because they are engineered as vehicle-grade computing terminals, not modified consumer tablets.

Technical strengths integrators value most:

✔ Interface flexibility for telematics, peripherals, sensors, and vehicle systems

✔ Stable communication backbone (LTE, Wi-Fi, GNSS, BT)

✔ High reliability under vehicle vibration & temperature extremes

✔ MDM support for remote updates, monitoring, and deployment

✔ Lifecycle longevity suitable for long-term industrial projects

✔ Consistent OS baseline supporting secure Android environments

This allows integrators to reduce system complexity, shorten deployment cycles, and provide long-term operational stability to their customers.

We continue to work closely with mobility integrators, fleet operators, and industry partners worldwide. If you’re deploying rugged MDTs in transit, logistics, or warehousing, our engineering team is happy to support your integration needs.